Introduction

Construction projects depend on fuel. Excavators, loaders, generators, and support equipment all require diesel to keep work progressing. When fuel runs out, equipment sits idle. When equipment sits idle, schedules slip and costs climb.

This guide addresses the operational questions construction companies face when managing fuel across active jobsites: how to coordinate delivery logistics, how to fuel equipment without disrupting work, and how to track consumption for project cost allocation.

Fox Fuel delivers diesel and off-road fuel to construction sites throughout Pennsylvania and New Jersey. This guide reflects the operational realities of jobsite fueling in our service area.

The Jobsite Fuel Challenge

Construction sites present distinct fuel management challenges that differ from fleet yards or fixed facilities:

Sites Move

Unlike a fixed depot, construction projects are temporary. A project may last three months or three years. Fuel delivery arrangements must adapt to changing site locations, access routes, and operational phases.

Access Changes

Site access conditions evolve as work progresses. Entry points that work during site preparation may become blocked during vertical construction. Delivery vehicles must navigate unpaved surfaces, grade changes, and active work zones.

Equipment Disperses

Equipment spreads across the site rather than parking in neat rows. Fueling may require reaching machines positioned in excavations, on elevated pads, or in congested staging areas.

Consumption Varies

Fuel consumption fluctuates with project phase. Earthwork burns diesel at different rates than finish grading. A generator supporting temporary power may run continuously or intermittently depending on grid availability.

Delivery Logistics for Active Sites

Coordinating fuel delivery to active construction sites requires advance planning and clear communication between the contractor and the fuel distributor.

Site Access Information

Before the first delivery, the fuel distributor needs to understand site conditions:

- Physical address and GPS coordinates for the delivery point

- Preferred entry gate or access road

- Surface conditions (paved, gravel, dirt, seasonal restrictions)

- Any height, weight, or turning radius limitations

- On-site contact name and phone number

- Security or check-in procedures

Delivery Timing

Construction sites often prefer fuel delivery during off-hours to minimize interference with active work. Common arrangements include:

- Early morning delivery before crews arrive — Equipment starts the day with full tanks

- End-of-day delivery after shutdown — Equipment is fueled and ready for the next morning

- Weekend delivery for larger sites — Bulk fueling without disrupting weekday production

Fox Fuel coordinates delivery windows with each site to match operational needs. Delivery timing is confirmed before dispatch.

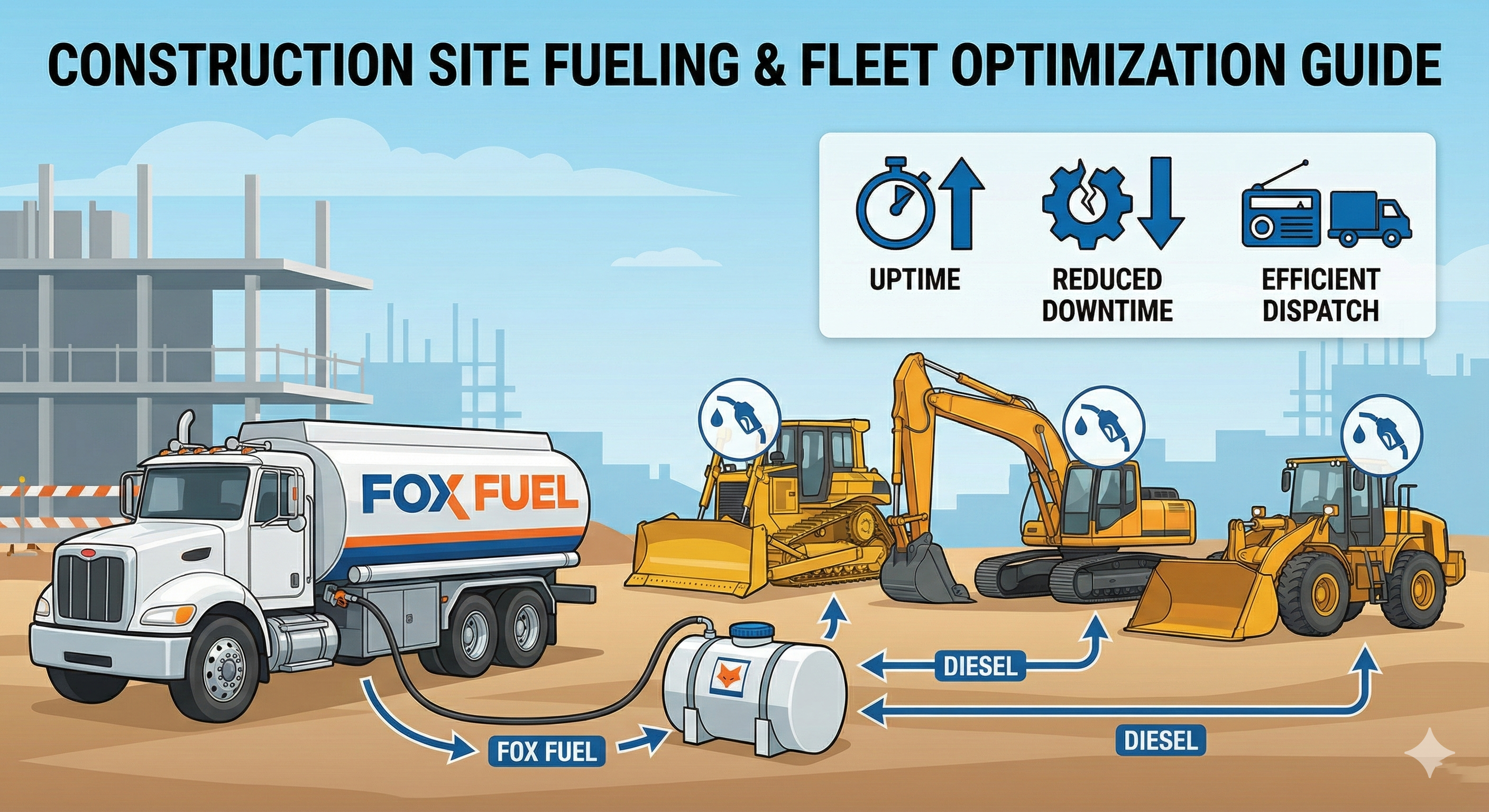

On-Site Tank vs. Direct Equipment Fueling

On-Site Storage Tank: A temporary above-ground tank is placed on site. The fuel distributor fills the tank periodically. Site personnel then fuel equipment from the tank as needed. This approach works well for larger sites with consistent consumption and secure storage locations.

Direct Equipment Fueling (Wet-Hosing): The fuel delivery truck moves around the site, fueling each piece of equipment directly. This eliminates the need for on-site storage and reduces theft risk. It works well for sites where equipment locations change frequently or where secure tank placement is difficult.

Fuel Types for Construction Equipment

Construction equipment typically uses one of two diesel products:

| Fuel Type | Common Uses | Tax Status |

|---|---|---|

| Off-Road Diesel (Dyed) | Excavators, loaders, dozers, generators, and other equipment that does not travel on public roads | Tax-exempt for off-road use; dyed red for identification |

| On-Road Diesel (Clear) | Pickup trucks, dump trucks, concrete trucks, and other licensed highway vehicles | Subject to federal and state highway fuel taxes; clear/undyed |

Fox Fuel delivers both off-road and on-road diesel to construction sites in Pennsylvania and New Jersey. Separate metering ensures accurate documentation for tax purposes.

Equipment Access Considerations

Fuel delivery drivers need to reach each piece of equipment. Site personnel can help by:

- Positioning equipment in accessible locations before delivery time

- Identifying machines that need fueling and their approximate locations

- Providing a site contact who can guide the driver or answer questions

- Communicating any safety requirements or restricted areas

The goal is equipment ready when crews arrive. Effective jobsite fuel management means equipment starts each workday with fuel in the tank. When fueling happens during off-hours or scheduled downtime, crews spend their time operating equipment rather than waiting for fuel.

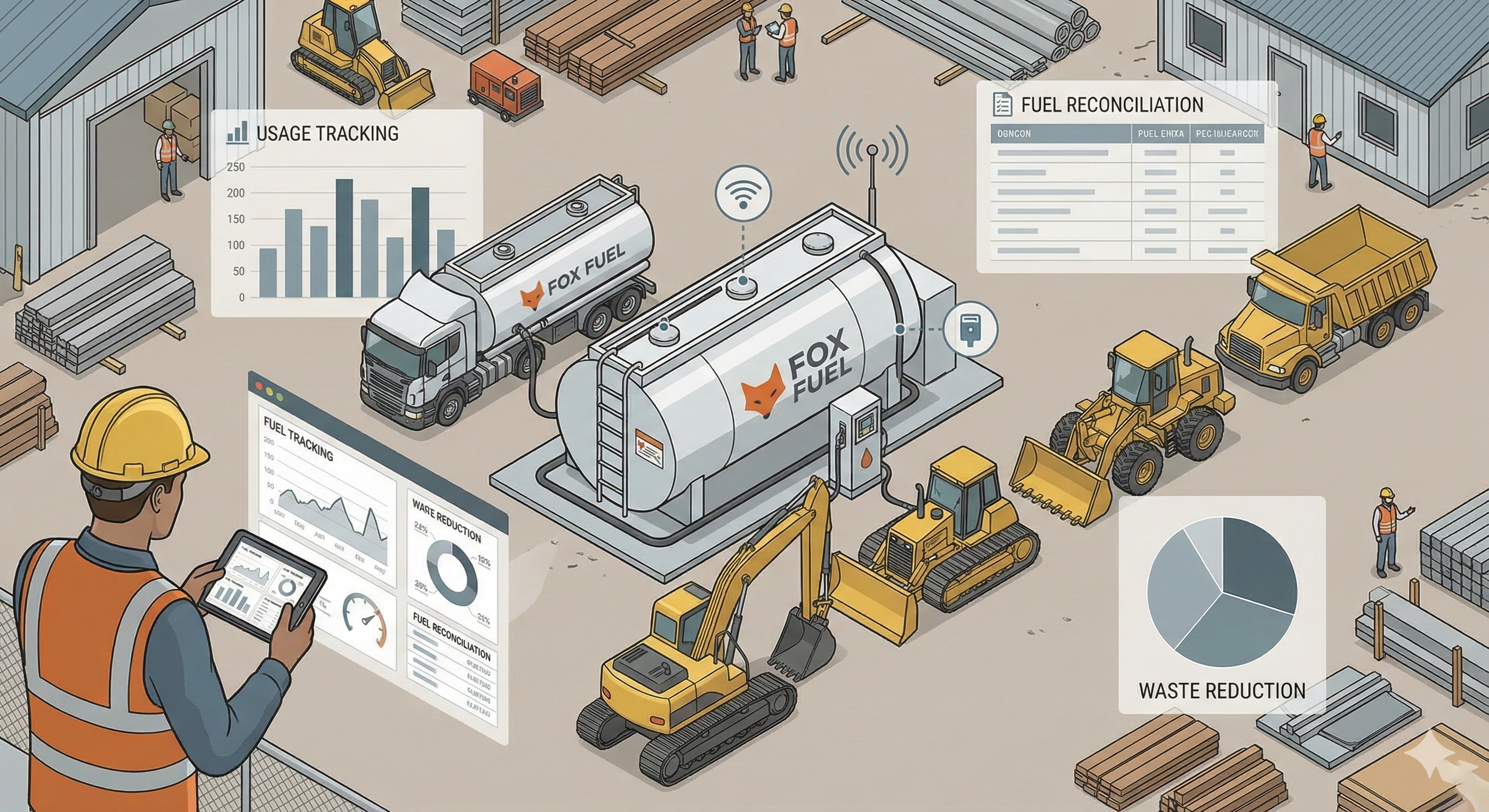

Project Cost Tracking

Accurate fuel cost tracking helps construction companies understand project expenses and improve future estimates.

Delivery Documentation

Each fuel delivery generates documentation that supports cost tracking:

- Delivery ticket with date, time, and location

- Gallons delivered by fuel type

- Equipment identification (when fueling individual machines)

- Signature confirmation

Fox Fuel provides delivery tickets at time of service and includes detailed information on invoices for accounting reconciliation.

Per-Equipment Tracking

For sites using direct equipment fueling, each machine can be fueled and recorded separately. This allows contractors to:

- Track fuel consumption by individual piece of equipment

- Identify machines with unusually high consumption

- Allocate fuel costs to specific job cost codes

- Build historical data for equipment cost analysis

Multi-Site Allocation

Contractors operating multiple projects can receive consolidated invoicing with clear site-by-site breakdowns. This simplifies accounting while maintaining project-level cost visibility.

Scheduling and Communication

Establishing a Delivery Schedule

Regular delivery schedules help prevent fuel shortages. The appropriate frequency depends on:

- Number and type of equipment on site

- Hours of operation

- Project phase and intensity of work

- On-site storage capacity (if applicable)

Fox Fuel works with contractors to establish delivery schedules that match project needs. Schedules can be adjusted as project phases change.

Communicating Changes

Construction projects change. Weather delays, schedule shifts, and access changes happen. Effective fuel management requires communication when:

- Site access points change

- Equipment is mobilized or demobilized

- Work hours shift significantly

- Weather or conditions affect site access

- Consumption changes substantially

Emergency and Unplanned Needs

Despite planning, urgent fuel needs occur. Fox Fuel maintains emergency dispatch for situations where equipment is unexpectedly out of fuel or a generator must run longer than anticipated. Contact dispatch directly for same-day or next-day emergency delivery.

On-Site Tank vs. Direct Fueling Comparison

| Factor | On-Site Storage Tank | Direct Equipment Fueling |

|---|---|---|

| Setup Required | Tank placement and containment | None — delivery truck comes to equipment |

| Fueling Flexibility | Site personnel fuel as needed | Scheduled fueling events |

| Theft/Loss Risk | Higher — fuel stored on site | Lower — no fuel stored between deliveries |

| Per-Equipment Tracking | Requires manual logging | Recorded at delivery |

| Best For | Larger sites with secure storage, steady consumption | Sites with changing layouts, security concerns |

Jobsite Fuel Management Checklist

Use this checklist when establishing fuel service for a new construction project:

- Provide site address and GPS coordinates

- Identify preferred entry point and any access restrictions

- Determine fuel type needs (off-road, on-road, or both)

- Decide between on-site tank or direct equipment fueling

- Designate a site contact for delivery coordination

- Establish preferred delivery timing

- Communicate site access changes promptly

- Position equipment for access before scheduled deliveries

- Review delivery documentation for accuracy

- Adjust delivery frequency as project phases change

How Fox Fuel Construction Fueling Works

Fox Fuel provides diesel and off-road fuel delivery to active construction sites across Pennsylvania and New Jersey.

Delivery Approach

- Scheduled delivery to your jobsite

- On-site tank fills or direct equipment fueling

- Off-road (dyed) and on-road (clear) diesel available

- Per-equipment metered delivery with documentation

- Delivery tickets provided for each fueling event

Service Requirements

- Accessible delivery point for fuel truck

- Site contact available for coordination

- Minimum volume requirements apply

Fox Fuel operates its own fleet from Pennsylvania, serving construction operations throughout the PA and NJ region. Emergency dispatch is available 24/7 for established accounts.